Our Technology

Nuclear energy, made at home

Strengthening US leadership through safe, affordable, scalable domestic enrichment.

Enrichment, made in America

Nuclear fuel production relies on five steps, taking uranium ore to finished fuel. American fuel production has a gap in the middle step, enrichment.

We are fixing this bottleneck using novel, scalable, cost-competitive technology. By reducing the cost of enrichment we will reduce the cost of nuclear energy.

1Mining & Milling

Uranium ore is extracted through conventional mining and milling or through modern in-situ recovery (ISR). A uranium powder called yellowcake (U₃O₈) is produced.

2Conversion

Yellowcake is converted from solid U₃O₈ into uranium hexafluoride (UF₆) gas through a chemical reaction. In gas form, different isotopes of uranium are more easily isolated.

3Enrichment

Uranium hexafluoride molecules are separated based on isotope. This refining process continues until the concentration of U-235 increases from its natural state (0.711%) to LEU (3-5%) or HALEU (5-20%). General Matter performs this enrichment step.

4Deconversion

A chemical reaction converts uranium hexafluoride gas into a solid, preparing it for fuel fabrication.

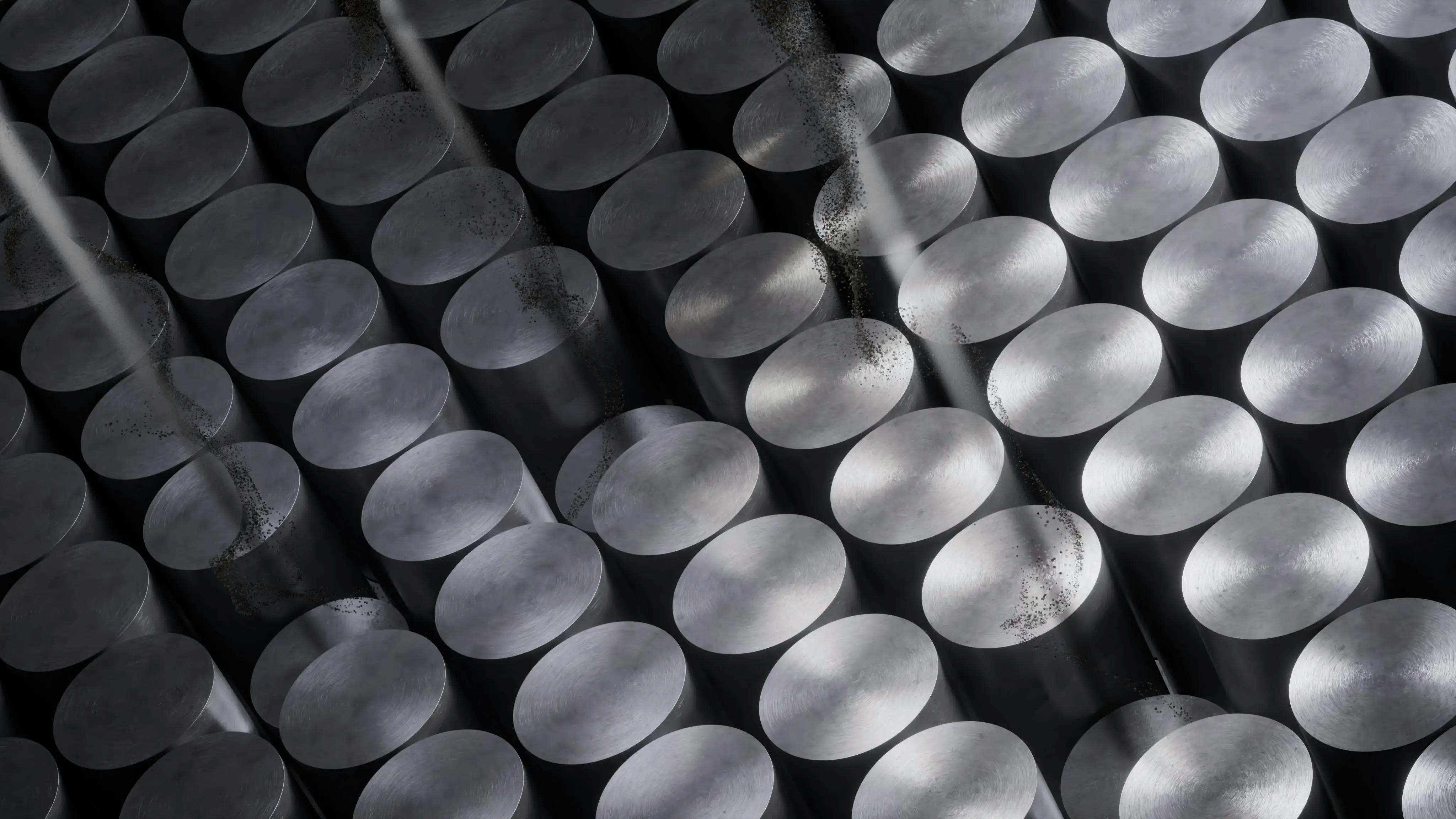

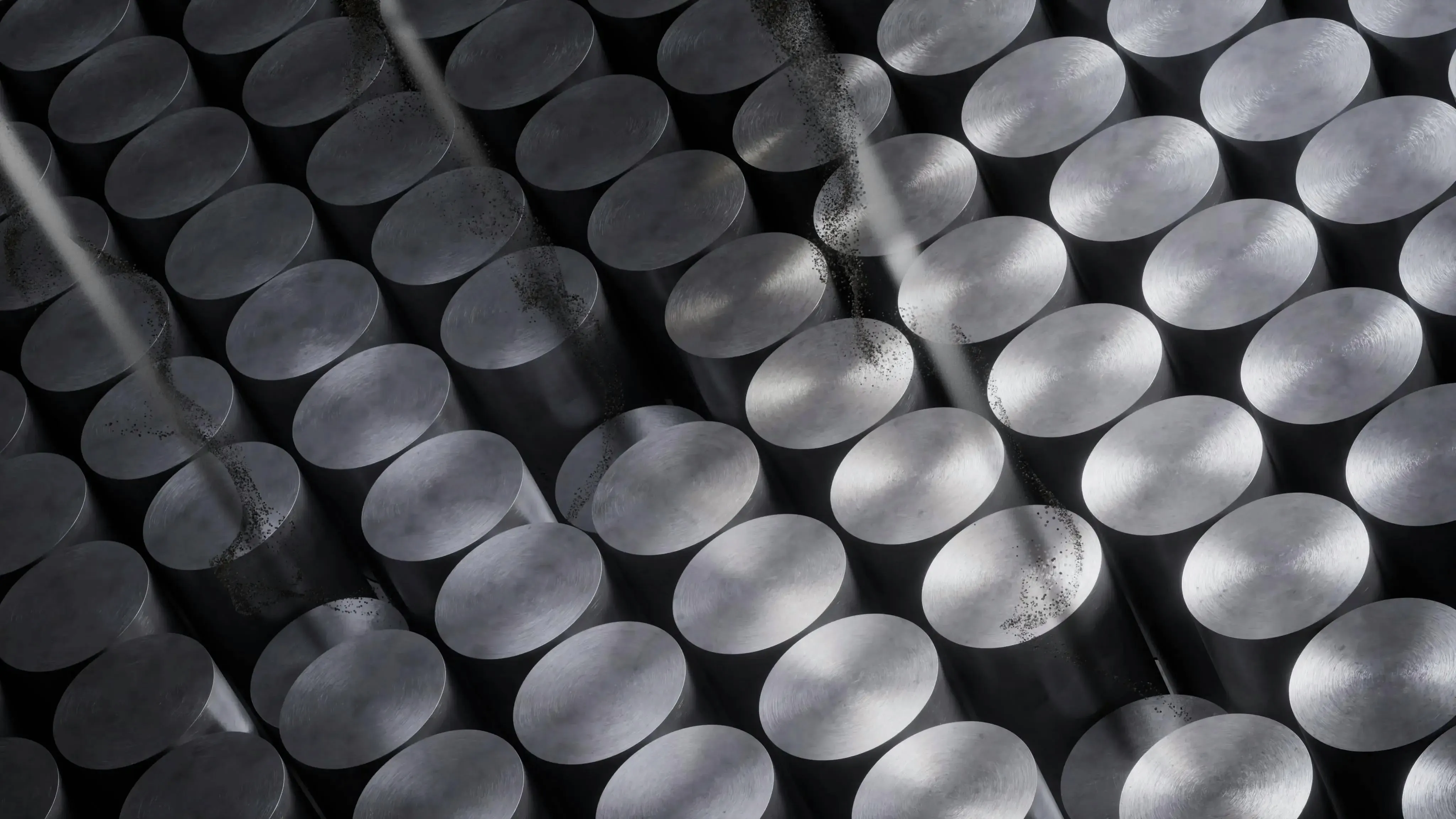

5Fabrication

Enriched uranium is formed into small cylinders or pellets, based on the reactor the fuel will be used in.